Home

The

Future of

Well Logging

Has Arrived

Increased ROP, producibility, reservoir understanding, and ESG initiatives are driving the energy industry to seek new measurement solutions and insights.

Diversified Well Logging (Diversified) partners with clients to lower finding and development costs, decrease the risk profile, increase reserves, and to improve capital efficiencies and returns on investment. We are on the cutting edge of innovation in the fields of robotics and automated sample collection, including quantitative measurements using robotics and AI data-driven solutions. Our technologies provide high-resolution and compositional analysis to assist our clients' operational activities with more safety, less risk, and increased certainty.

Explore

Diversified's Solutions

RoboLogger™️

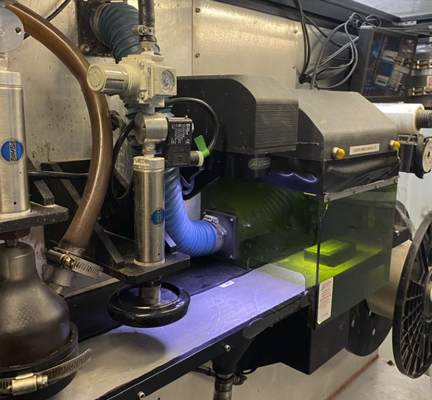

The RoboLogger™ is the industry’s only fully automated sample collection and elemental analysis device.

It is designed to collect and store up to 350 samples (25 grams to 30 grams) at a maximum rate of 2 minutes per sample. The RoboLogger™ depth-stamps each sample with a barcode and can take white-light images prior to wrapping or storing. Each sample can be viewed remotely.

Surface Measurement While Drilling™️

Surface Measurement While Drilling™️, or SMWD™️, makes the full potential of cuttings available.

Geological uncertainty within the well or across a field is reduced with the delivery of quantitative elemental data in realtime. Our XRF field specialists assure data quality with rigorous laboratory standard checks and sample depth verification. All realtime data may be used by our artificial intelligence software to enhance drilling efficiency, improve geosteering, and completion optimization.

Geosteering

Diversified has steered over 16 Million feet of hole over the past 10 years using traditional GR curves to guide us. Building on this expertise, we now utilize unique Python scripting incorporating elemental data from cuttings to steer wells with greater confidence, stay in-zone, and avoid hazards. Additionally, our chemostratigraphers utilize binaries to better define stratigraphic packages and formation tops.

Elements also mitigate the measure of uncertainty that GR data exhibits in certain formations. Elemental steering increases the geological knowledge and confidence in correct geopositioning. Both lead to improved completion strategies and profitability.

Wellbore Surveillance

Diversified is invested in the success of every well it logs. Our Wellbore Surveillance services mitigate problems and the resultant non-productive time.

We integrate engineering and geologic data for our A.I. software to improve drilling efficiency in realtime.

Fluid & Gas Analysis

We take the hydrocarbon gas and fluid potential of individual wells and perform correlations of trends across pads or fields.

Using mud logging chromato- graphic data as a base, we evaluate, we correlate, we deliver data necessary for geologists and engineers.

Classic Mud Logging

Classic Mud Logging

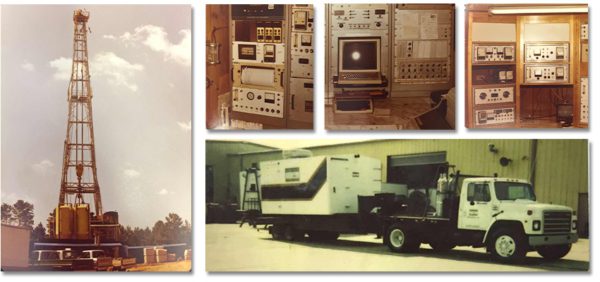

Quality and reliability in realtime geological services has made Diversified Well Logging a trusted partner for seventy years

Diversified deploys its mud logging cabins offshore and onshore throughout the United States.

Classic Geosteering

Diversified Well Logging has successfully geopositioned wells in most of the major USA unconventional shale basins.

Currently operations are focused in the Permian Basin and Appalachian region.

Discover

Who We Are at Diversified

Today,

Diversified continues to create and provide innovative services to drive capital efficiency across oilfields around the world.

At the peak of our activity between 2014 to 2016, we were running over 100 jobs, 7 of which in deepwater, and we have since begun an industry revolution with automation and robotics-driven sample catching technology.

In 1952,

Diversified Well Logging, LLC., began its operations in the Gulf of Mexico - offshore Louisiana - and expanded by moving into land-based operations as the unconventional boom began to take off.

Since its foundation Diversified has always been proud to be a part of the dynamic oil and gas industry, and has always strived to be a step ahead of the challenges and changes the industry has gone through. The drive for innovation and improved efficiency continues today.

Diversified Well Logging

Diversified Well Logging